Case studies

BiogasGasMix

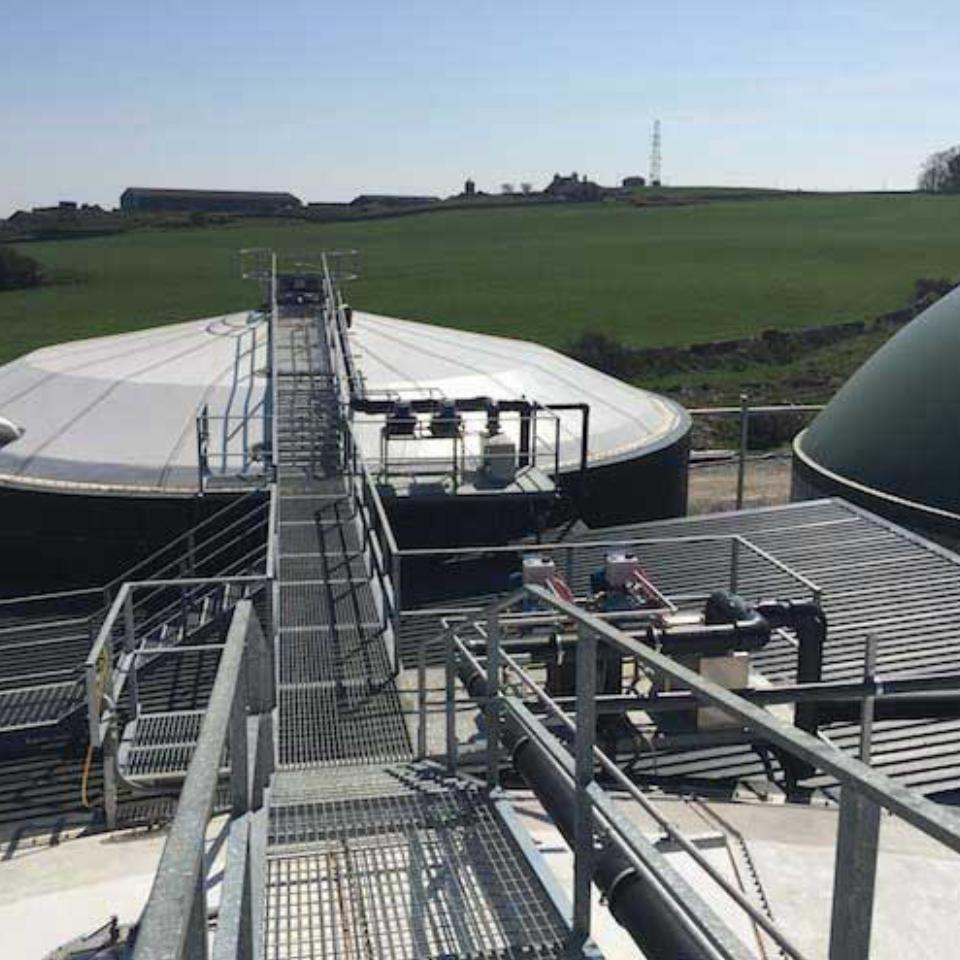

Overhaul of digester mixing system delivers better biogas yields

Eco Verde Energy's revamped Anaerobic Digestion plant in Suffolk now boasts higher biogas yields thanks to Landia's superior mixers and pumps. This significant upgrade, overcoming past inefficiencies, marks a leap in renewable energy efficiency and sustainability.

Wastewater

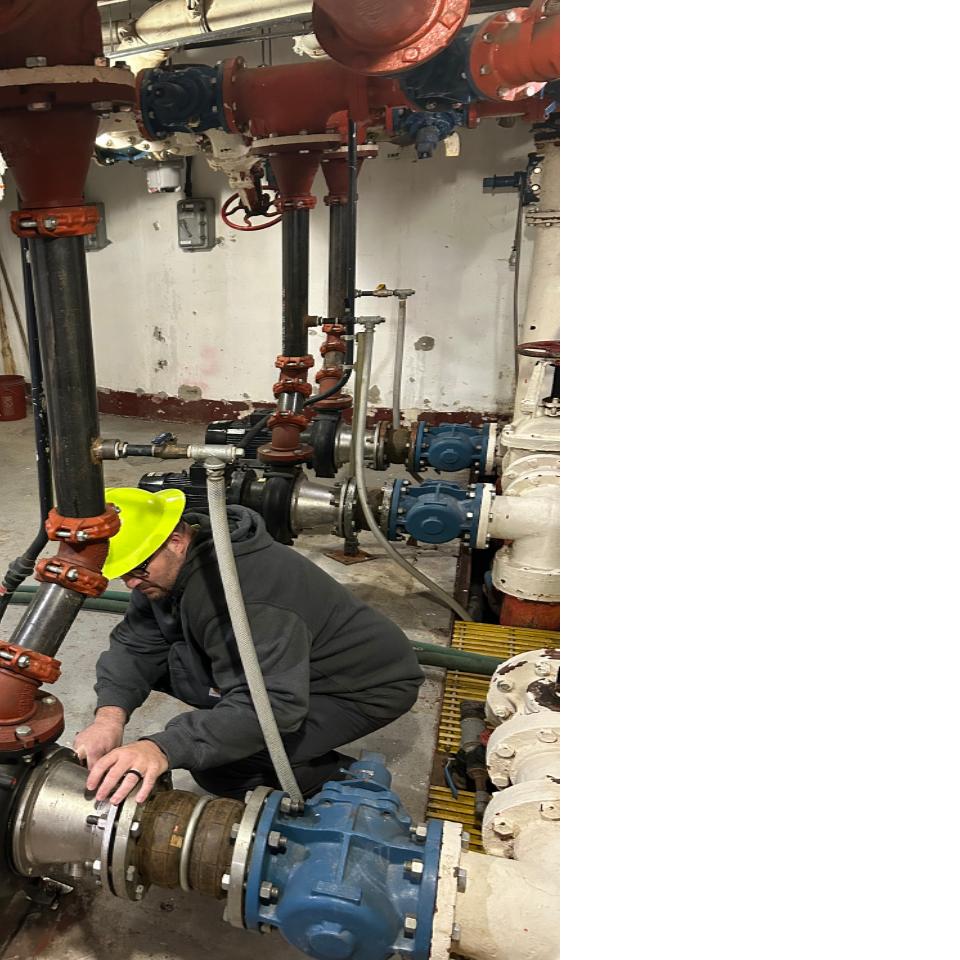

Daphne finds prime solution for primary problematical lift station

Suck it up, pressurize it and send it to the treatment plant. In theory, this should be a straightforward job for pumps at a lift station. However, as we all know, the curse of so-called ‘flushable’ products in our sewer systems is also proving that some so-called ‘non-clogging pumps’ are getting clogged.

Wastewater

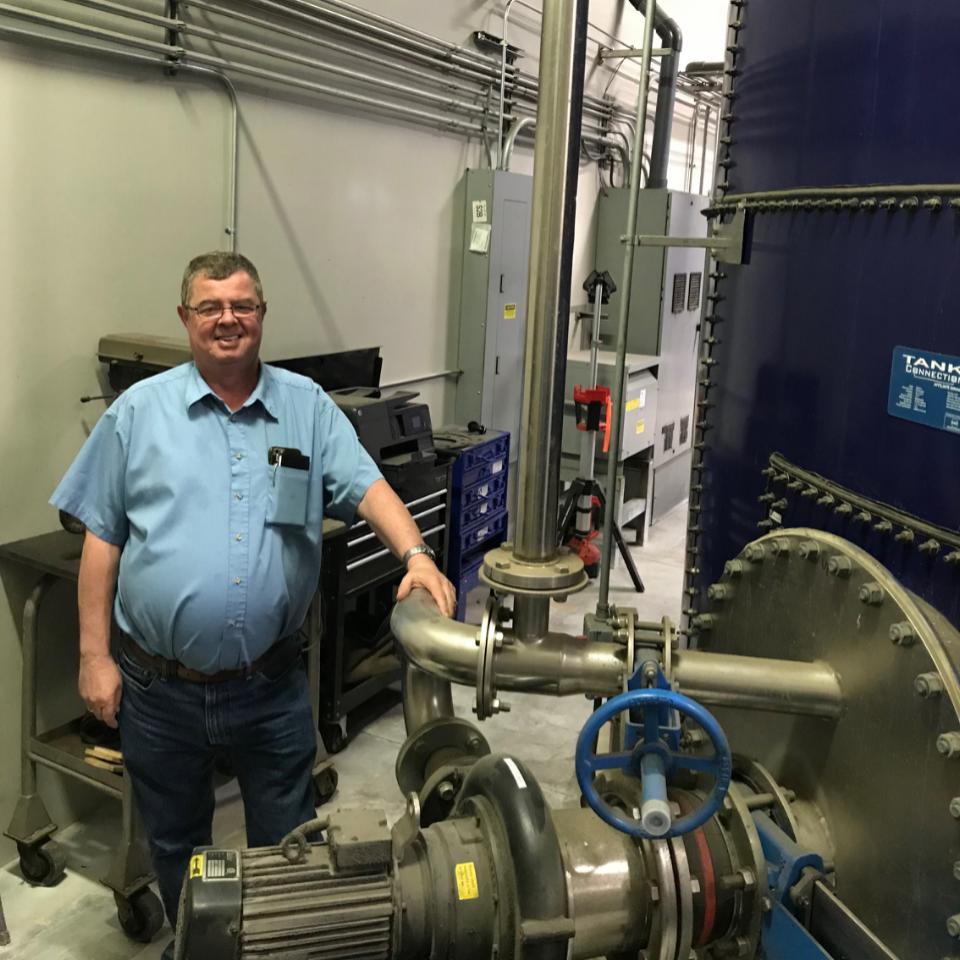

The Valley Center way - combining energy savings now – with Total Cost of Ownership

At Valley Center Wastewater Treatment Plant, and at an increasing number of facilities across Kansas, the decision to buy the more expensive equipment at the outset is proving to be the most economic. Savings in long-term maintenance are important, but in the shorter term, energy savings are fundamental.

Wastewater

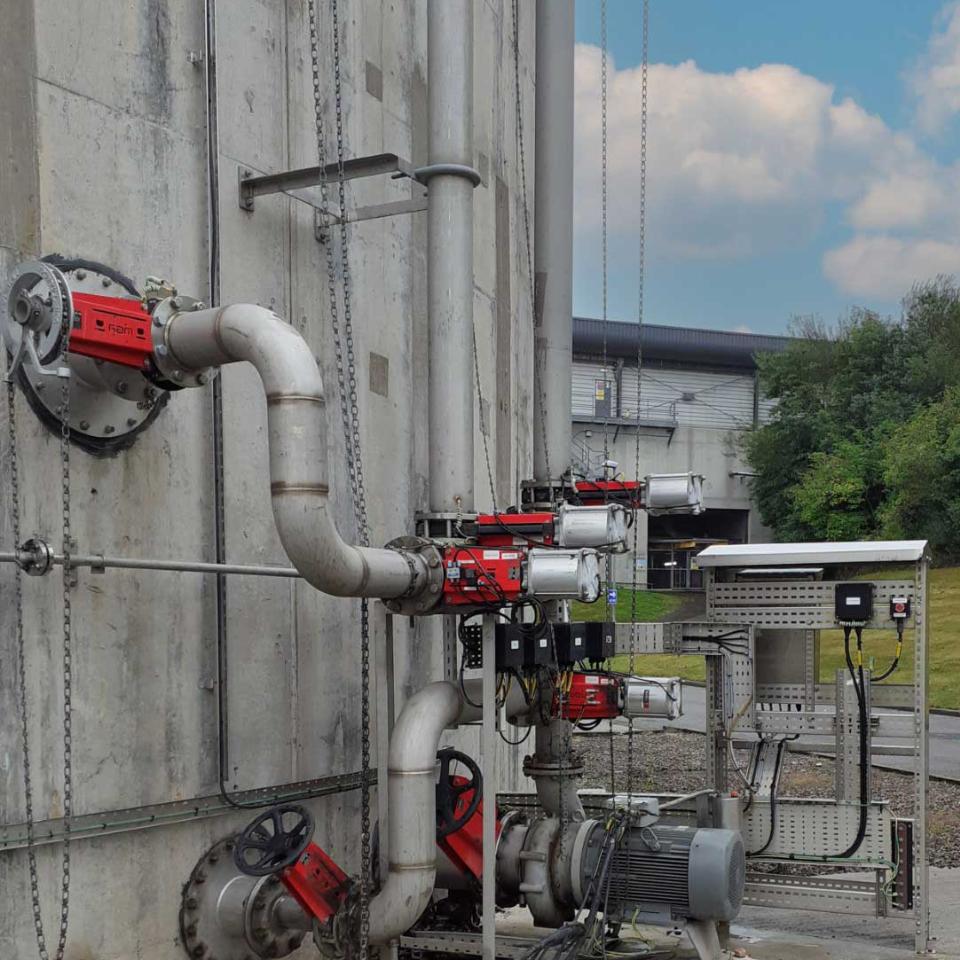

New biogas production landmark for Scottish Water’s acclaimed sludge facility at Nigg

If we took a short trip forward in time to 2040, and then looked back at how some organisations in the water industry successfully achieved Carbon Net Zero, it’s likely you’ll see a large four-letter word: NIGG.

WastewaterBiogasGasMix

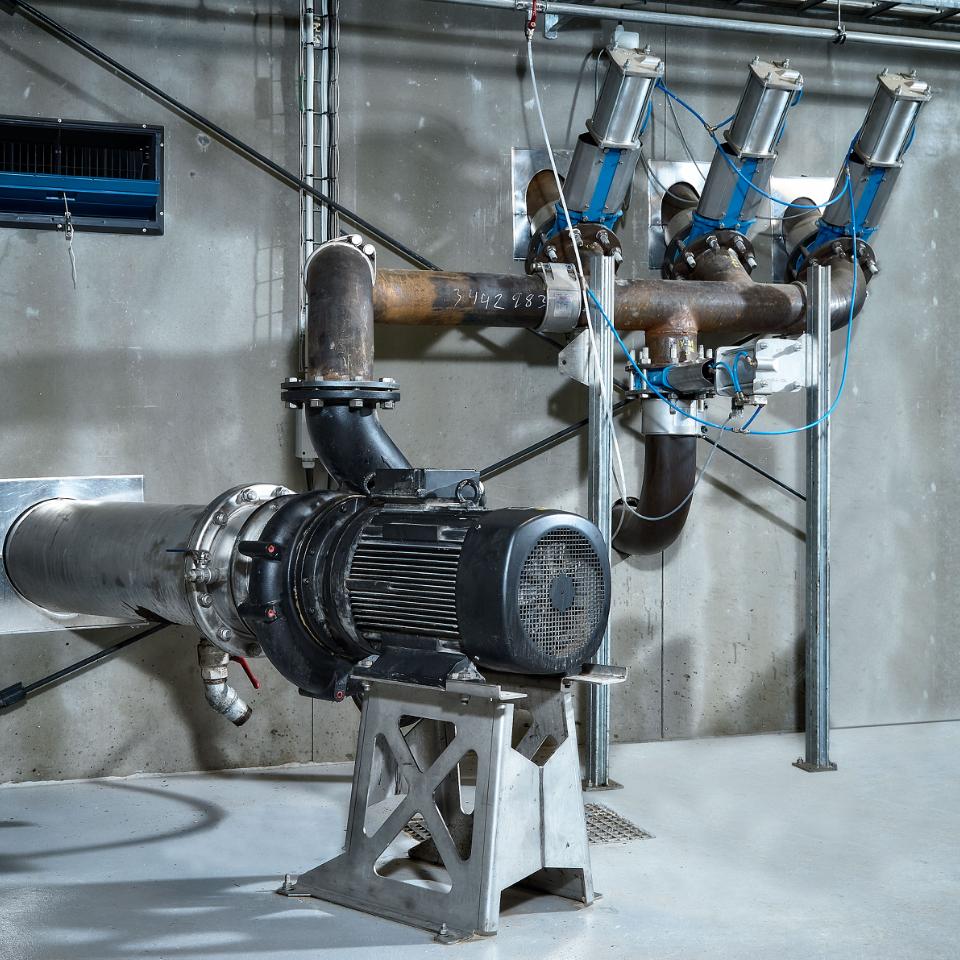

Mix to the max at Yorkshire Water’s major new Energy & Recycling Facility

At Yorkshire Water’s new £50M Huddersfield Energy and Recycling Facility (E&RF), the digester mixing system from Whitchurch-based Landia is ensuring that total gas production can reach its anticipated 22,192Nm³/d (normal cubic meter/day).

Biogas

Food waste pump proves itself at largest University Biogas Plant

At the largest University campus AD/Biogas plant in the United States, a chopper pump made by Landia has now completed eight years of continuous robust service, despite the very tough environment of being in a food waste and FOG (fats, oils and greases) reception pit.

AgricultureIndustryBiogas

Pioneering farmer shows pig industry the benefits of renewables

A pioneering pig farm in North Carolina, US, that has led the way in its industry for embracing renewable technologies, has reported a 10% plus increase in its biogas yields by investing in two new chopper pumps made by Landia.

IndustryWastewaterGasMix

Landia and Cambi help deliver big upswing in biogas production for the water industry

Just south of Aberdeen, improvements continue to be made at Scottish Water’s Sludge Treatment Centre (STC) in Nigg – but at a site still approaching its full potential, 0.9~1.0MW per tonne of Dry Solids is already being consistently produced.

Wastewater

Greaseballs gone as new pumps get to work

Situated approximately halfway between two of America’s largest cities, Madisonville (population 4396) might not deal with the same mega volumes of wastewater that are treated in Dallas and Houston, but for its highly dedicated team, there is never any let up in their commitment to their city’s treatment plant.

Wastewater

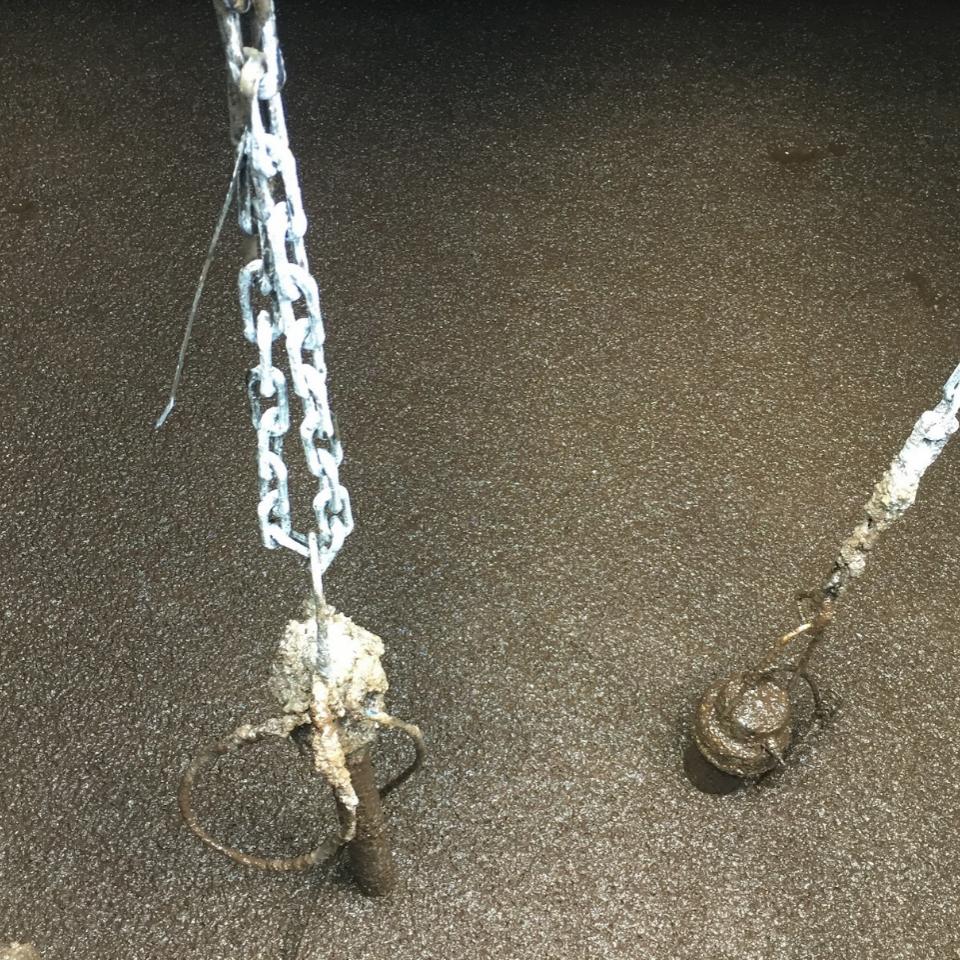

Forward dive for long-lasting Landia mixers at St Andrews

Following an intricate diving operation, ESD (the joint venture involving Galliford Try, MWH Treatment and Black & Veatch) has completed the successful upgrade of its mixing operation at Scottish Water’s Wastewater Treatment Plant (WWTP) in St Andrews, Fife.

IndustryWastewater

MSE Systems bring in Landia pumps & mixers to help treat potato effluent

Following the successful installation two years ago of Landia Chopper Pumps and a Landia Aeration System, MSE Systems is set to install a further three units from Landia for one of the UK’s leading supplier of potatoes.

IndustryWastewater

New Poultry Wastewater installation taken care of by Watermark Projects and Landia

Watermark Projects (part of leading engineering services company, W.A Cooke & Sons) has introduced a Landia mixing system to help handle wastewater at an expanding organic poultry producer in South Wales.