Handling slurry with straw

If you use a lot of straw in the barns, you need an effective slurry management system that prevents clogging.

Landia provides efficient pumping and automatic control.

Related products

Efficient handling of slurry with straw

The most used system in pig pens is vacuum (see drag and drop). The amount of straw that can be used in this system is limited without any problems with emptying the troughs under the slats. Especially in older pens with 250 mm slurry pipes, straw will build up in the system during sluicing and cause problems.

When straw consumption increases, the slurry pumps will often work overtime. The pumps will typically stop, and it is difficult to get the slurry out of the pen.

By installing the right pump, which can increase the vacuum power, the problem is solved.

In newer pens with 315 mm slurry pipes, more straw can be used. How much depends entirely on the type of straw, how often it is drained, how much is washed and the number of pigs in the pen.

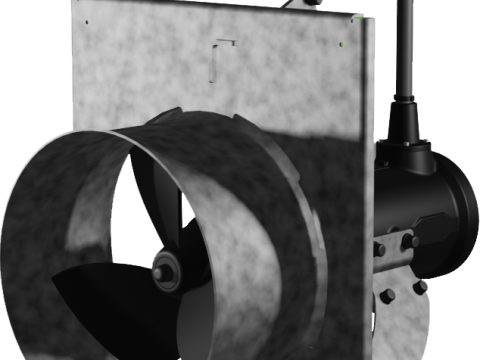

However, here it is possible to mount a pump directly on the slurry pipe from the barn: it can increase the vacuum effect when sluicing takes place and alleviate many problems.

A complete solution with a pump and PE pump well is easy and there is no need to invest in a reception tank.

Efficient pumping with fully automatic control

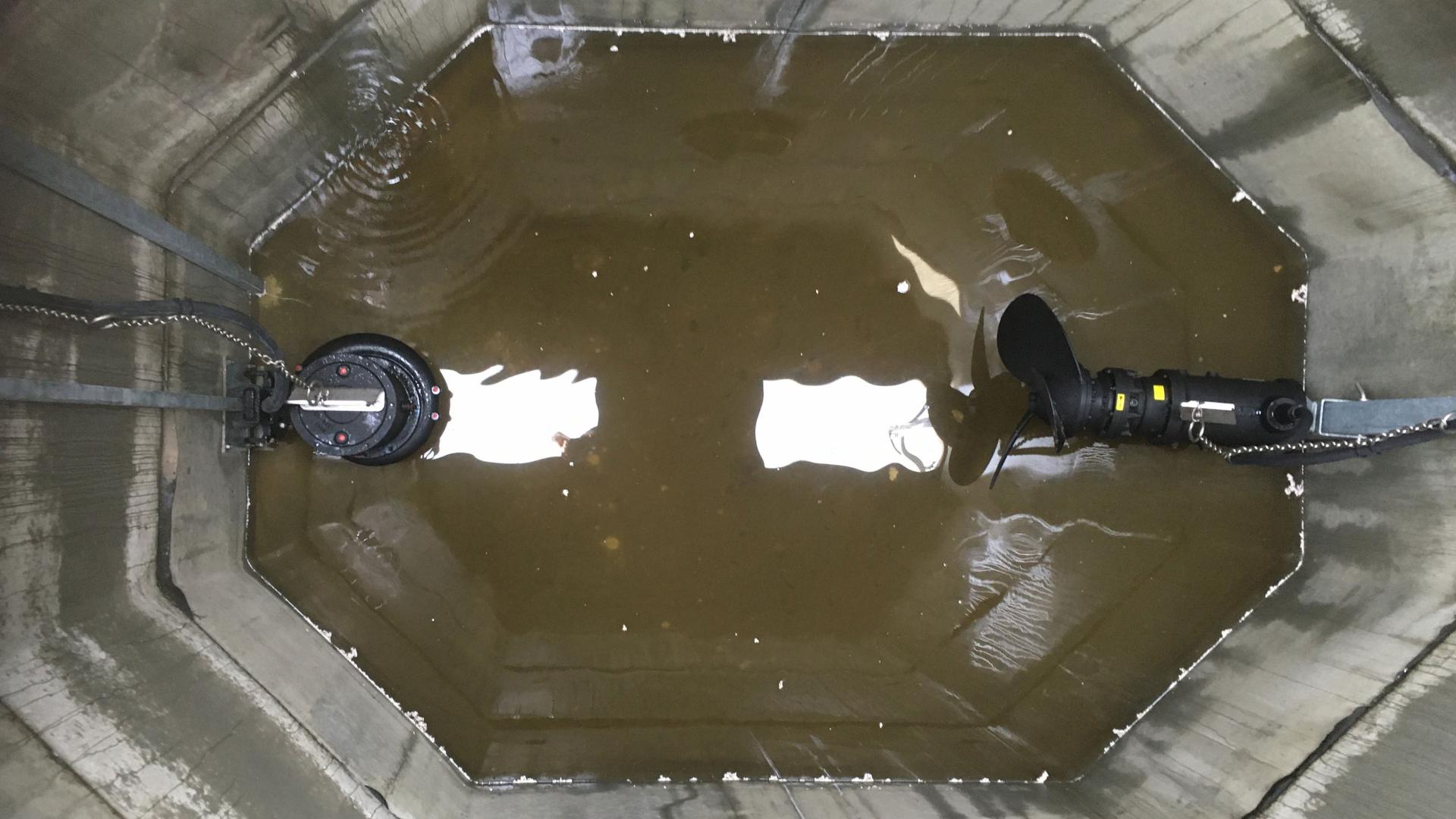

In several newer welfare stalls, there is line play in the slurry channels, which is required when larger amounts of straw are used. Here, slurry and straw are scraped into the reception tank. Most often it is supplied in a transverse channel, where backflushing takes place. When more straw comes into the reception tank, mixing will often be required.

We recommend placing a mixer and a pump with a knife system in the reception tank. To solve problems with incorrect slurry handling and a high time consumption, automatic control can be an excellent solution. It even handles mixing and over-pumping at the right time. It provides less wear on the pump and mixers at the same time as there is also a great time saving and an easier transition for new employees who need to be trained in the farm’s slurry handling when everything is running automatically.

Landia supplies slurry pumps, all with a knife system, mixer, electric controls and wells.

A strong partner with solid experience in agriculture

You will find, with all due modesty, no one with greater experience in solutions for pumps and mixers for agriculture than Landia.

We have been involved from the very beginning in Denmark, and today you will find Landia products on farms worldwide. The structure of agriculture is constantly evolving, and we keep up with it.

When you contact Landia, you will speak with employees who know the industry and have extensive technical know-how.