Pump mixing for wastewater

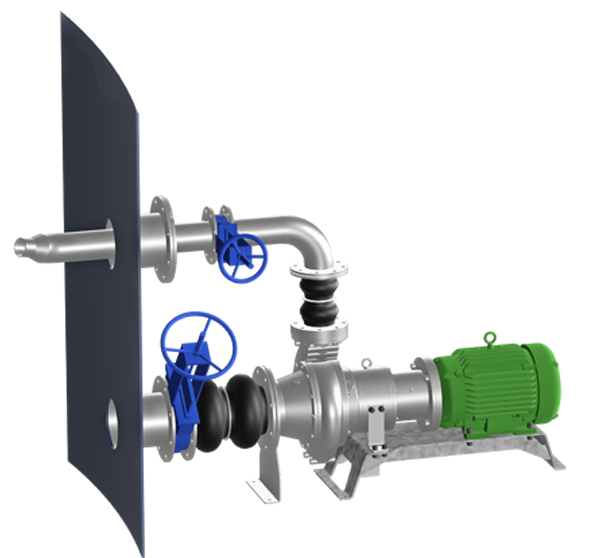

With the Landia JetMixer mixing system, all mechanical components are located outside the tank. Therefore, it is not necessary to open or empty the tank when performing service or repairs on the system.

It offers both purely safety benefits, but of course also financial benefits: the operation can continue without any problems during service work on the Landia JetMixer system.

The benefits of pump mixing sludge

Landia JetMixer works by recirculating the liquid in the tank and creating mixing using the nozzles located in strategic levels in the tank. This provides an even speed distribution throughout the tank. At the same time, it is possible for the system to create concentrated mixing in specific zones.

Landia JetMixer can be used with most tank types and at tank volumes up to approx. 10,000 m³. At the same time, it is usable for sludge with DM up to 14%. The mixing effect can be documented with CFD simulation.