Aeration with an ejector aerator

The Landia AirJet is an ejector aerator that works by automatically sucking the air into the ejector and subsequently mixing it with the wastewater during combined mixing and aeration.

Related products

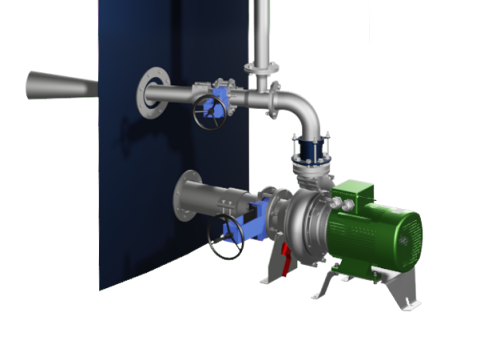

Chopper pump with ejector system

The AirJet consists in all its simplicity of a chopper pump that has been fitted with an ejector system. Compared to most other aeration systems, the AirJet is extremely easy to install and control.

There is no need for compressors, bottom-mounted diffusers and advanced controls.

The Landia AirJet can be installed in both existing and new tanks. In some cases, there is no need to empty the tank before the system is installed. The AirJet is available in a submersible version as dry-installed and floating mounted on a pontoon.

Photo: Roquette

AirJet – easy and efficient

With the Landia AirJet you get a simple and efficient aeration system. It can be your actual source of aeration, to counteract bothersome odours, and additional aeration at peak loads or as a replacement for worn-out rotor or surface aerators.

The AirJet is ideal for heavily polluted wastewater and, since the system does not stop, the aerator has a constant efficiency – unlike most other types of aeration.

A strong partner with extensive experience in wastewater

Finding a partner with extensive experience in wastewater management is crucial, and frankly, there’s no one out there with more experience in wastewater mixers than Landia.

Since the late 1980s, when we supplied our first mixers for sewage treatment plants, Landia products have found their way into sewage treatment facilities worldwide. The wastewater industry has been growing steadily year after year, and we’ve been growing right along with it.

When you get in touch with Landia, you’ll be speaking with people who aren’t just familiar with the industry; they’re enthusiastic about it, just like you.