Chopper pumps deal with the wastewater – without stopping

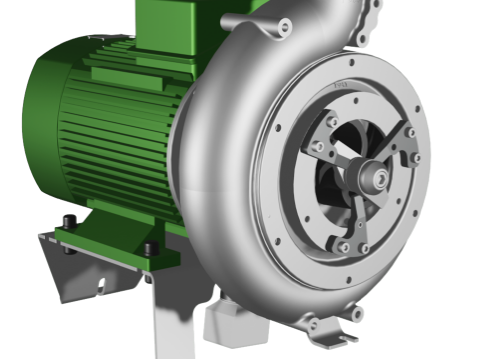

The Landia’s chopper pumps break down impurities before they are pumped further into the system and therefore act as a problem solver in pumping stations.

Related products

No more pump alarms

There are very few wastewater pumps on the market that can handle the many disposable cloths, wet wipes, nappies, leftover clothes and other foreign bodies that end in the sewer and so the wastewater, and it is never convenient when a pump alarm kicks in.

Landia’s series of chopper pumps are fitted with an efficient knife system at the pump inlet. The pump chops impurities before they are pumped further into the system and a Landia chopper pump is a permanent solution to solve problems with clogged pumps.

Easy adaptation to an existing installation

A Landia chopper pump can be adapted to the installation equipment of most other pump manufacturers, so it is both quick and simple to upgrade your pumping station with a Landia chopper pump. Regardless of pump performance and installation conditions, you get a tailor-made pump solution for the specific task.

If it is not possible to replace your existing pump with a Landia pump, there is also a solution: Landia Eradigator is a chopper pump that recycles the contents of the pump station, breaks down impurities and crusts and counteracts clogging of your existing pump. Installed in no time and just needs to be connected to power.

A strong partner with extensive experience in wastewater

Finding a partner with extensive experience in wastewater management is crucial, and frankly, there’s no one out there with more experience in wastewater mixers than Landia.

Since the late 1980s, when we supplied our first mixers for sewage treatment plants, Landia products have found their way into sewage treatment facilities worldwide. The wastewater industry has been growing steadily year after year, and we’ve been growing right along with it.

When you get in touch with Landia, you’ll be speaking with people who aren’t just familiar with the industry; they’re enthusiastic about it, just like you.