GasMix Digester Mixing System for wastewater

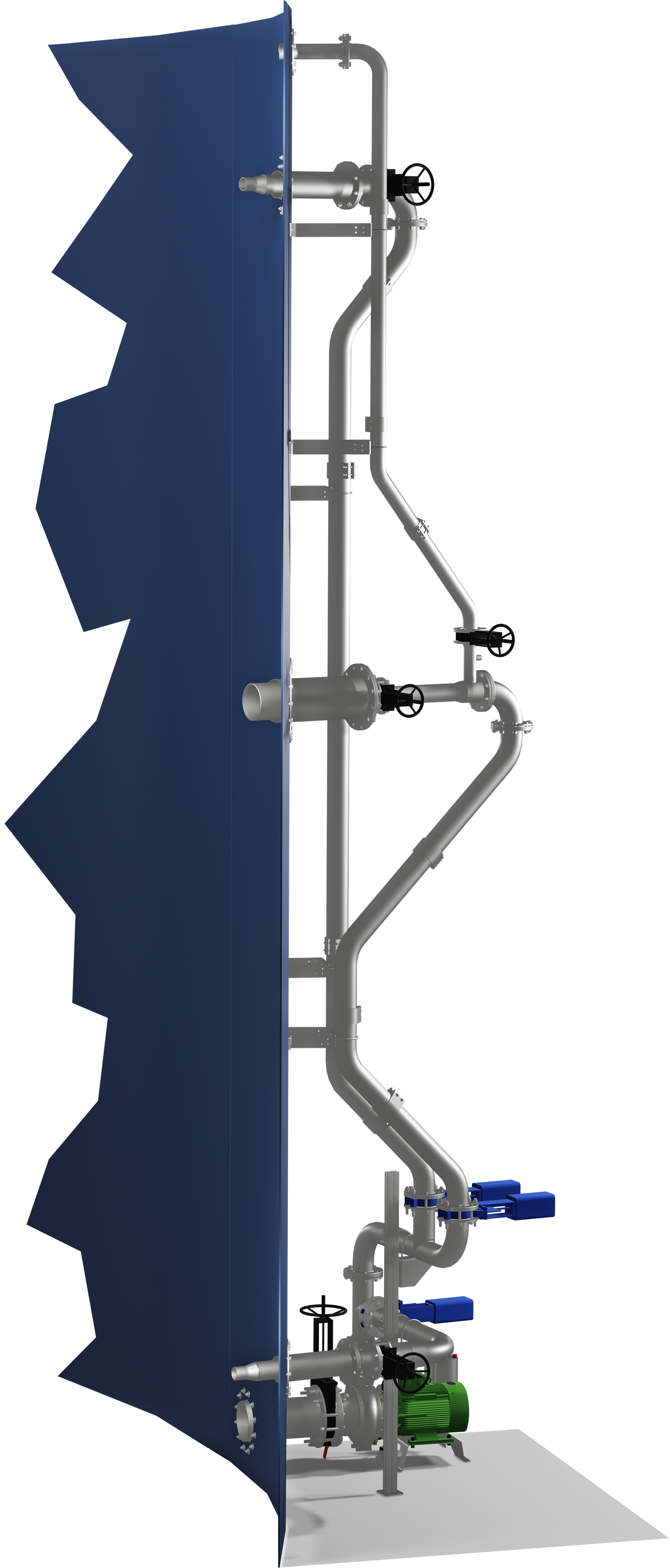

Landia GasMix is a mixing system for anaerobic digesters. GasMix has all the mechanical components located outside the tank. Therefore, it is not necessary to open or empty the tank when performing service or repairs on the GasMix system.

This provides benefits both purely in terms of safety, but also economically, as biogas production can continue unhindered during service work on the GasMix system.

How Landia GasMix works for wastewater

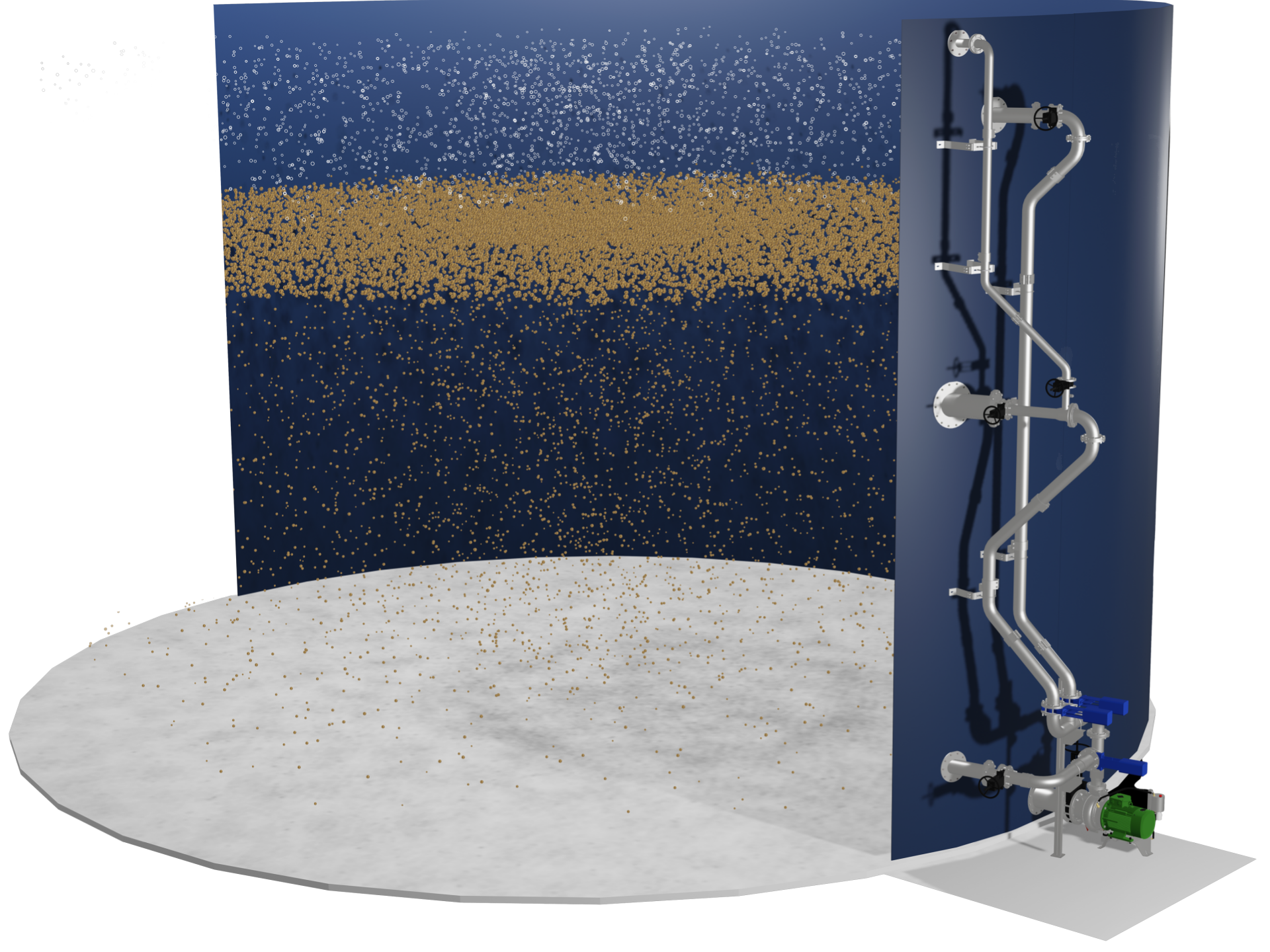

The mixing with Landia GasMix works by recycling a mixture of liquid and biogas in the tank. This keeps the tank contents uniformly mixed and supports a stable and efficient digestion process.

It has been documented that the GasMix system leads to effective sludge reduction.

Landia GasMix can be used with most tank types, at volumes up to approx. 10,000 m³ and for sludge with DM up to 14%. The mixing effect can be documented with CFD simulation.

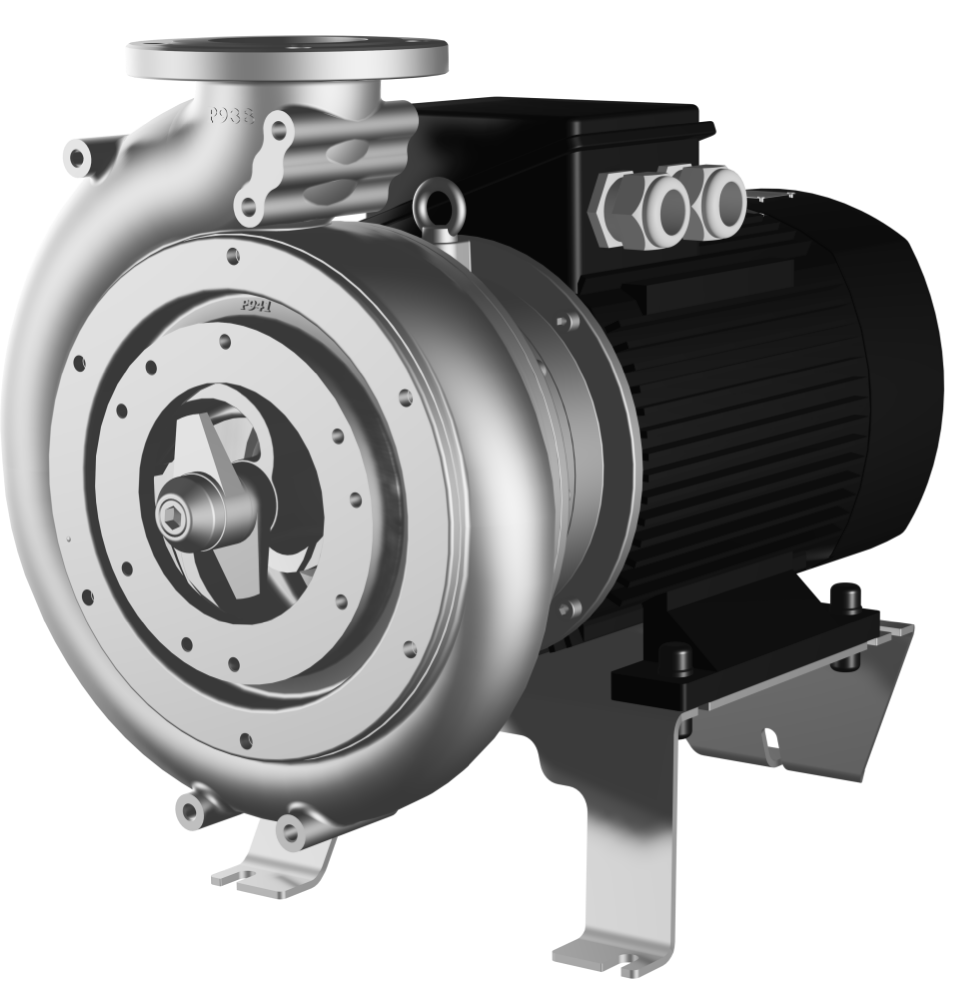

Chopper Pump MPTK-GI

| Capacities | up to 475m3/h |

| Heads | up to 50m |

| Motor sizes | 15.0 - 37.0kW |

| Available with | Ex motor / IE3 motor |

Landia GasMix - How does it work?

Our solutions within wastewater

Mixing sludge

More than 40 years with solutions for mixing sludge in sewage treatment plants.