MBBR mixing in the fish industry

Efficient and gentle mixing in MBBR reactors.

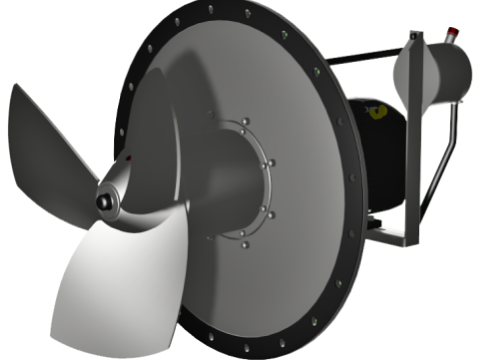

Related products

About 30 years of mixing in MBBR processes

The MBBR process consists of a carrier media, so-called carriers or biomedia, which are small plastic elements on which the biofilm can grow. The carrier media must be in contact with the wastewater, so mixing is necessary.

Landia has about 30 years of experience with mixing in MBBR processes and has a wealth of experience. It is important that the carrier media is mixed as efficiently and gently as possible. Gentle means that the impact from the mixer is as small as possible, as harsh treatment can cause damage to the plastic elements.

No wear on the carrier media – no wear on the propeller

The contact between the carrier media and the propeller creates friction and so potential wear. Landia BioMover mixers for MBBR all have a low propeller tip speed of between 3 and 8 m/s, and they so they provide optimal protection of the plastic elements.

All Landia propellers are made of stainless steel with a material thickness of 6-8 mm. They have proven to be virtually impossible to wear out in MBBR applications – unlike certain other types of propeller material.